We are happy to help you find the right pump for your project. To do this, we need as much information as possible about the type of work the pump will perform:

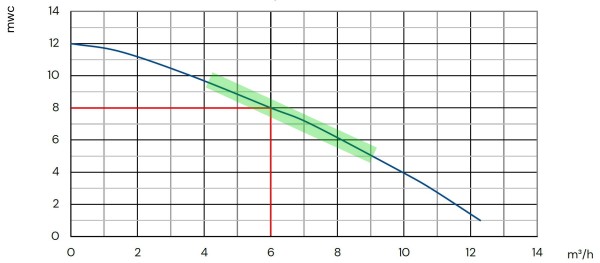

The pump curve is a curve that visually represents the performance of a pump.

The horizontal axis shows the flow rate (in m³/h), and the vertical axis shows the pump head (in m). The right end of the curve is the maximum flow rate of the pump, and the left end is the maximum head (above which no more water flows from the pump).

To check the flow rate at a certain head (8 m in the example), start from the vertical axis and go to the right until you touch the curve line. Then go down until you reach the horizontal axis and see the corresponding flow (6 m³/h).

It is best to use the pump in the middle third of the curve (the green part).

Some graphs have multiple curves, depending on the speed of the motor (rpm). It is important to look at the correct curve.

Cavitation can be recognized by a rumbling sound. It occurs when the pressure at the pump's outlet is greater than at the inlet. When the pressure drops below the vapor pressure, vapor bubbles form in the liquid, which then implode upon reaching the higher-pressure section. This can damage pump components.

The best way to prevent this is to use the appropriate pump and piping. Therefore, it is always recommended to discuss your complete application with us our team we can provide you with a suitable offer.

When temperatures drop below the freezing point, it's important to prepare stationary pumps for the cold weather. Do this by draining all the water from the pump housing (using the drain valve) and the hoses. If not, the water can freeze and damage the pump and hoses.

DOL and Star-Delta are different starting methods.

With DOL (direct-on-line), an induction motor is connected directly to a three-phase power supply. During starting, a very high current (5 to 8 times the full load current) flows through the motor.

With Star-Delta, the motor winding has six floating terminals. In the starting position, full voltage is applied to the motor with "D" opened and "S" closed (connection in star). Once the motor has almost reached its maximum speed, the connection is converted to delta by closing "D" and opening "S." The starting current can be reduced to one-third of the current required for DOL starting.

WANT TO KNOW MORE? MAKE AN APPOINTMENT?

Do you have questions? Ask them here and we will contact you as soon as possible!

Contact us